DIN 931 outlines the specifications for hexagonal head bolts. These bolts are commonly used in diverse applications, from automotive engineering toassembly.

The DIN 931 standard covers sizes such as head size and thread form. It also sets standards for material quality and precision.

Adhering to DIN 931 ensures durable connections and boosts the performance of components.

Socket Head Cap Screws: Understanding DIN 931 Specifications

DIN 931 specifies the engineering requirements for hex head bolts, commonly referred to as socket head cap screws. These fasteners are widely utilized in numerous automotive applications due to their durability. here The DIN 931 standard covers parameters such as thread pitch, head diameter, and material grade.

- Complying to DIN 931 ensures the interchangeability of hex head bolts from different suppliers, facilitating efficient assembly and repair processes.

- The standard also includes allowances for key dimensions, guaranteeing consistent performance and reliability.

ISO 931 - Strength and Reliability in Fastening Solutions

When it comes to robust and reliable fastening solutions, DIN 931 sets the industry standard. This widely recognized specification outlines strict requirements for hex bolts, ensuring they deliver exceptional strength and durability across a variety of applications. From construction and manufacturing to automotive and aerospace, DIN 931 fasteners are known for their consistent quality and dependable performance. Manufacturers adhere to these stringent guidelines to guarantee that every product meets the highest standards of precision engineering, making them ideal for demanding environments and critical joinings.

- Meeting with DIN 931 standards ensures fasteners are manufactured with precise dimensions and tolerances.

- The specification covers a range of metals, including steel, stainless steel, and brass, providing options for diverse applications.

- Inspection procedures ensure the strength and reliability of DIN 931 fasteners under various load conditions.

By choosing DIN 931 fasteners, engineers and manufacturers can confidently rely on a proven solution that delivers exceptional performance and longevity.

Durable Hexagon Bolts: DIN 931 Explained

DIN 931 specifies the standards for high-performance hexagon bolts, commonly utilized in applications demanding exceptional strength and durability. These screws are produced from premium steel alloys, providing superior strength against wear, fatigue, and corrosion. DIN 931 also outlines precise dimensions for the bolt's head, shank, and thread profile, ensuring proper fit and secure fastenings.

- Frequently used in automotive, aerospace, and industrial applications

- Offer high tensile strength and yield strength

- Offered in a range of sizes and thread pitches

Applications of DIN 931 Hex Head Bolts

DIN 931 hex head bolts play a crucial role in various industries due to their strength. These screws possess a hexagonal head which allows for convenient tightening using a wrench. Their adaptability makes them suitable for situations requiring light to medium duty fastening requirements. Some common applications of DIN 931 hex head bolts include construction, equipment assembly, and general purpose fastening.

Selecting Appropriate Materials for DIN 931 Bolts

When determining materials for DIN 931 bolts, several factors must be considered. The intended application of the bolt will heavily influence the most suitable material. For instance, if the bolt is to be used in a critical environment, materials with high tensile strength, such as stainless steel, are required. Conversely, for applications requiring protection from environmental factors, materials like brass might be more appropriate. Furthermore, the bolt's temperature range can also influence material choice, with some materials performing better at extreme heat levels.

Additionally, factors like budget constraints and availability can also play a role. Consulting with engineering specialists and adhering to relevant guidelines are crucial steps in ensuring that the chosen material for DIN 931 bolts is both suitable and dependable.

Torque Specifications for DIN 931 Hex Head Bolts

DIN 931 hex head bolts have a wide range of uses in mechanical fixings. Proper torque specification is crucial for ensuring the integrity and reliability of these connections. Refer to the manufacturer's guidelines or industry standards to determine the appropriate torque setting for your specific grade. Over-tightening can damage the bolt threads or adjacent components, while under-tightening can result in a loose connection prone to failure.

- Regularly use a calibrated torque gauge for accurate tightening.

- Grease threads according to the manufacturer's recommendations.

- Inspect bolts after installation for any signs of damage or improper alignment.

Dimensions of DIN 931 Bolts

DIN 931 bolts are a crucial component in various industrial and mechanical applications. These standardized fasteners exhibit precise specifications that ensure reliable connections. A comprehensive understanding of DIN 931 bolt sizes and dimensions is essential for selecting the appropriate bolts for specific projects.

DIN 931 bolts are characterized by their hex head and coarse thread, which allow for secure fastenings in a variety of materials. The sizing system of DIN 931 bolts comprises a range of metric diameters, denoted by the letter M followed by a numerical value. For instance, an M8 DIN 931 bolt has a diameter of 8 millimeters.

- Moreover, the length of a DIN 931 bolt is measured from the underside of the head to the end of the thread. The length is expressed in millimeters and corresponds to specific design requirements.

- Provided in various lengths, DIN 931 bolts can be selected to accommodate different application needs .

Consulting the official DIN 931 standard provides detailed information on bolt sizes, thread pitches, tolerances, and other relevant factors.

Corrosion Resistance in DIN 931 Bolts

DIN 931 bolts are widely utilized for their strength, but their performance is heavily influenced on their ability to withstand corrosion. The {specificmaterial composition of the bolt plays a vital role in determining its resistance to degradation. Common materials used for DIN 931 bolts include steel, with stainless steel offering superior defense against corrosive environments.

A selection of surface coatings can also be applied to DIN 931 bolts to improve their corrosion resistance. Choices such as zinc plating, galvanizing, and powder coating provide a protective barrier against corrosive agents like moisture, salt, and chemicals.

When selecting DIN 931 bolts for applications subject to rusting, it is crucial to carefully consider the unique environmental conditions and choose materials and treatments that provide adequate protection.

Thread Pitch and Length Variations in DIN 931

DIN 931 specifies various studs with a shaft section, providing flexibility in design and application. The standard encompasses several options of thread diameters, typically expressed in millimeters per revolution. This diversity allows for optimal coupling based on the specific requirements of the assembly.

Furthermore, DIN 931 defines multiple thread lengths to suit diverse scenarios. These lengths are typically specified in millimeters and ensure a secure and reliable connection between components. The combination of various thread pitches and lengths enables engineers to select the most appropriate DIN 931 fastener for their design.

- Specification DIN 931 outlines various thread pitches and lengths.

- Thread pitch variations allow for different engagement levels between components.

- Length variations cater to diverse application needs and assembly requirements.

Hex Bolts Compared to Other Fasteners

When it comes selecting the optimal fastening system for a particular application, engineers and fabricators must carefully evaluate various factors. Among the diverse options available, hex head bolts (DIN 931) stand out as a popular choice due to their durability. Compared to other fastening systems such as carriage bolts, hex head bolts offer several strengths. Their hexagonal head grants a firm grip for socket drivers, allowing for secure and trustworthy tightening.

Furthermore, the thread design of DIN 931 bolts are meticulously designed to ensure a snug fit within the mating hole. This accuracy contributes to their ability to withstand heavy loads and vibrations.

- The robustness of hex head bolts renders them suitable for applications involving high force.

- Differently, machine screws often lack the same level of strength, while carriage bolts are primarily designed for stationary setups.

- As a result, hex head bolts (DIN 931) present a multifunctional fastening solution that effectively combines strength, reliability, and ease of use.

Ensuring Quality Assurance of DIN 931 Hexagon Bolts

DIN 931 hexagon bolts hold a reputation for their strength and reliability in various industrial applications. To ensure this high standard, stringent quality assurance measures get put forth throughout the manufacturing process. These steps encompass a broad spectrum of inspections, from raw material sourcing to final product testing.

Every component, including threads, heads, and shafts, receives rigorous scrutiny. Dimensional tolerances are strictly controlled to adhere to the DIN 931 requirements.

Moreover, tensile strength and fatigue resistance tests are performed to verify the bolt's ability to tolerate heavy loads. By sticking to these rigorous quality assurance guidelines, manufacturers ensure that DIN 931 hexagon bolts consistently offer the expected performance and dependability.

Meeting Specification Requirements for DIN 931 Bolts

DIN 931 bolts are renowned for their durability. To ensure consistent quality and performance, these fasteners must strictly adhere to the guidelines outlined in the relevant regulations. Compliance with DIN 931 bolting standards ensures a number of key benefits. These include accurate thread dimensions, proper material composition, and precise dimensions for optimal fastening performance.

- Additionally, adherence to DIN 931 standards contributes to enhanced safety and reliability in applications ranging from automotive and aerospace to construction and manufacturing.

- Stringent testing protocols are employed throughout the manufacturing process to confirm compliance with these essential standards.

By selecting DIN 931 bolts that meet these rigorous specifications, engineers and manufacturers can confidently achieve secure and dependable fastenings in a wide variety of applications.

DIN 931 in Industrial Applications

DIN codes 931 defines the technical requirements for a specific type of bolt, known as a hexagon head bolt. These fasteners are widely used in various industrial sectors due to their durability and reliability.

Common applications for DIN 931 screws include construction projects, where they are often assembled to parts of varying strength. The precise specifications outlined in the DIN 931 code ensure a secure and reliable joint, contributing to the overall stability of the system.

- Moreover, DIN 931 fasteners are often selected for their flexibility in terms of material and dimensions.

- Commonly, they are fabricated from iron materials, providing high resistance.

- Furthermore, their shape allows for easy installation using standard tools.

Fastening Solutions for Automotive Industry with DIN 931

The automotive industry relies on/depends on/needs robust and reliable fastening solutions to ensure vehicle safety, performance, and longevity. DIN 931, a widely recognized standard for hexagonal head/cap/top bolts with a fine/medium/coarse thread, plays a crucial role/part/function in this regard. These fasteners offer exceptional strength/durability/robustness, making them ideal for applications where high-load conditions/situations/environments are present.

Automotive manufacturers often utilize/employ/use DIN 931 bolts in critical components such as engines, transmissions, suspension systems, and bodywork. The standard's stringent requirements/specifications/guidelines ensure consistent quality, dimensional accuracy, and reliable performance. Furthermore, the versatility/adaptability/flexibility of DIN 931 bolts allows them to be used in/applied to/fitted with a wide range of materials, including steel, aluminum, and plastics.

- Pros of DIN 931 Bolts in Automotive Applications:

- High Tensile Strength

- Corrosion Resistance

- Precise Threading for Secure Fastening

- Durability/Longevity/Robustness under Harsh Conditions

- Wide Range of Sizes and Materials to Suit Diverse Needs

Choosing DIN 931 Fasteners

When specifying DIN 931 bolts for an application, several engineering aspects must be carefully assessed. These include the material class of the bolt, which should correspond with the required tensile and yield strengths. Furthermore, the thread pitch needs to be compatible with the threaded hole. Other crucial parameters include bolt length, head style, and surface finish, all of which must be optimized to meet the specific application demands.

- In conclusion , a thorough understanding of the specified load conditions and environmental influences is essential for ensuring the proper selection of DIN 931 bolts.

Regular Maintenance and Inspection of DIN 931 Bolts

DIN 931 bolts are a vital component in many engineering applications, and their reliable performance depends on proper maintenance and inspection. Frequent inspections allow for the early detection of deterioration, preventing potential failures that could result in property damage. A comprehensive inspection should encompass the bolt's thread condition, checking for any signs of corrosion. It is crucial to follow the manufacturer's recommendations for maintenance intervals and inspection procedures.

- Periodic lubrication can help minimize friction and prolong the life of DIN 931 bolts.

- Bolt tension should be carefully controlled during installation to avoid under-torquing to the bolt or surrounding components.

- Documentation of inspections and maintenance activities are essential for tracking the condition of DIN 931 bolts over time.

Case Studies: Successful Implementation of DIN 931

DIN 931 standardized hex head bolts are a critical component in many engineering applications. Showcasing their value, numerous case studies highlight the efficient implementation of DIN 931 bolts across diverse sectors. One such example involves a leading aerospace firm that opted to incorporate DIN 931 bolts in their structure assembly process. The result? A substantial reduction in joint failures and an overall augmentation in product strength. Another case study showcases a power generation company that adopted DIN 931 bolts for their heavy-duty equipment. This installation led to increased operational efficiency and reduced maintenance costs. These real-world examples underscore the consistency of DIN 931 bolts as a superior solution for demanding applications.

Advantages of Using DIN 931 Hex Head Bolts

DIN 931 hex head bolts are a versatile and robust fastener solution widely used in various applications. Their high tensile strength and durable construction make them ideal for resisting heavy loads and vibrations. The hexagonal head provides a secure grip and allows for easy tightening with wrenches. Additionally, these bolts offer excellent corrosion resistance, ensuring their longevity in demanding environments.

- Due to its exceptional strength properties, DIN 931 hex head bolts are frequently used in construction, automotive, and industrial applications.

- A hexagonal shape provides a strong grip and prevents rounding during tightening operations.

- These bolts are available in a range of sizes and materials to cater specific application requirements.

The DIN 931 Standard

DIN 931 outlines the requirements for a range of bolts, specifically hexagon head screws. This international specification provides essential parameters regarding the size of the hardware, thread, and material. It also includes acceptable variations to ensure interchangeability with corresponding threaded connections.

- Furthermore, DIN 931 is widely used in engineering applications where durability is paramount.

- Adherence with this standard ensures consistency in the production and use of bolts, contributing to the robustness of various mechanical systems.

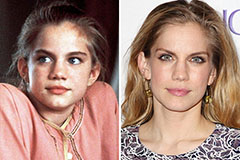

Emilio Estevez Then & Now!

Emilio Estevez Then & Now! Kel Mitchell Then & Now!

Kel Mitchell Then & Now! Anna Chlumsky Then & Now!

Anna Chlumsky Then & Now! Rachael Leigh Cook Then & Now!

Rachael Leigh Cook Then & Now! Jane Carrey Then & Now!

Jane Carrey Then & Now!